In management systems, quality, health, safety and environment are highly important aspects and issues. For continuous improvement of quality, efficiency and systems, balanced scorecards have been used as a technique for benchmarking HSE performance. As there is no single measure of QHSE performance, a basket of measures is required.

This basket of measures or a balanced scorecard provide information on a range of quality, health, safety and environment activities.

For example, organisations solely use injury and ill-health statistics to measure their health and safety performance. The UK’s Health and Safety Executive pointed out that there are many drawbacks to this as there is no necessary relationship between occupational injury statistics and control of major accident hazards. Injury statistics only reflect outcomes and not causes.

Find also: QHSE in construction – A detailed guide

They cannot emphasise enough the need for more proactive or upstream measures of performance. This translates to more concrete things to measure like the number of training courses or inspections.

The balanced scorecard approach aims to address the absence of a systematic approach in deriving QHSE measures and how they link to the risk control process. It provides a framework to help you create a more disciplined approach to quality, health, safety, and environment performance measurement—to ensure that your measurement is effective and you’re effectively using your resources to measure your performance.

This article will illustrate a methodology that systematically integrates QHSE functions with business functions in operational procedures and their performance measurements. As this is based on the HSE’s Guide to Measuring Health and Safety Performance, this article will use health and safety issues to illustrate the concepts but take note that they equally apply to other QHSE functions.

Why do we have to measure performance?

To answer this difficult question, here are the bulleted answers as summarised (and slightly edited) from the HSE guideline:

- To provide information on the progress and current state of your strategies, processes and activities used to control risks to your QHSE. Information derived from your performance measurement sustains your operation and the development of your QHSE system as the control of risks by:

- Providing you with information on how your system operates

- Identifying areas and aspects where remedial action is needed

- Providing a basis for continual improvement

- Providing feedback and motivation

Remember, effective performance measurement provides information on the level of your performance and why it is performing as such. If your measurement information cannot be used by any means to understand the basis of your performance, then it is useless.

- To answer questions in order to provide a complete picture of your organisation’s QHSE performance. These are the questions your performance measurement should seek:

- Where are we now relative to our overall QHSE aims and objectives?

- Where are we now in controlling hazards and risks?

- How do we compare with others?

- Why are we where we are?

- Are we getting better or worse over time?

- Is our management of QHSE effective (doing the right things)?

- Is our management of QHSE reliable (doing things right consistently)?

- Is our management of QHSE proportionate to our hazards and risks?

- Is our management of QHSE efficient?

- Is an effective QHSE management system in place across all parts of the organisation (deployment)?

- Is our culture supportive of QHSE, particularly in the face of competing demands?

Ask these questions in all your various management levels and across your organisation. The aim of which is to have a complete overview of your company’s QHSE performance.

- To help you with decision making. Your performance measurement helps you in deciding:

- Where you are relative to where you want to be

- What progress is necessary and reasonable in the circumstances

- How that progress might be achieved against specific restraints (for example, resources or time)

- How that progress might be achieved

- Priorities and effective use of resources

- To address different information needs in your company. Information derived from your QHSE performance measurement is needed by the people in your company with responsibilities within your QHSE system—this includes your directors, senior managers, line managers, supervisors, QHSE professionals and employees and representatives. These people need specific information to their position and responsibilities within your QHSE system. There should be an overall harmony in your measurement approach so that individual activities are aligned with the overall performance measurement framework. A heirarchical set of linked measures should be set out in order to reflect the overall organisation structure.

Even though your primary focus for your performance measurement is to achieve internal needs, the capability to demonstrate to your external stakeholders that you have a system to control QHSE risks is highly desirable.

Related reading: Get your employees involved in your QHSE initiatives today.

What should my company measure?

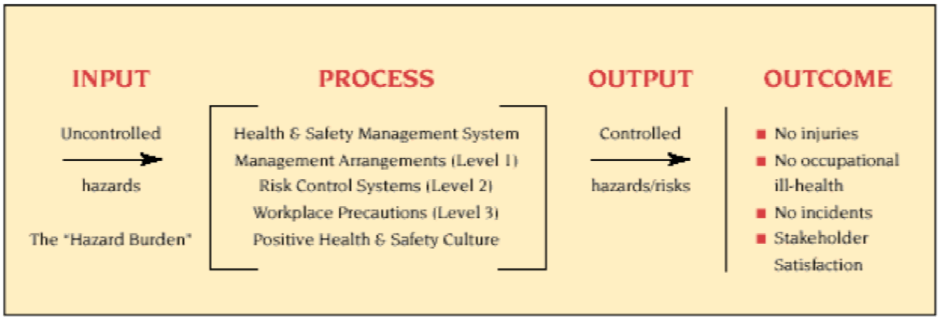

For this part, we will illustrate using health and safety functions to answer the question. Effective risk control in health and safety management is founded on an effective management system that is illustrated on this HSE figure:

There are three levels of control for this kind of health and safety management system (HSE, 2001):

- Level 3- effective workplace precautions provided and maintained to prevent harm to people at the point of risk.

- Level 2- risk control systems (RCSs): the basis for ensuring that adequate workplace precautions are provided and maintained.

- Level 1- the key elements of the health and safety management system: the management arrangements (including plans and objectives) necessary to organise, plan, control and monitor the design and implementation of RCSs.

And to effectively answer the question, “What is our health and safety performance”, the measurement should cover all elements laid out in the above illustration. It should be based on a balanced approach which combines (HSG 65, 2001):

- Input: Monitoring the scale, nature and distribution of hazards created by the organisations activities – measures of the hazard burden;

- Process: Active monitoring of the adequacy, development, implementation and deployment of the health and safety management system and the activities to promote a positive health and safety culture-measures of success; and

- Outcomes: Reactive monitoring of adverse outcomes resulting in injuries, ill health, loss and accidents with the potential to cause injuries, ill health or loss – measures of failures.

Measure your hazard burden

Any activity undertaken can create hazards that will vary in nature and significance and the hazard burden will determine the risks needed to be controlled. In order to measure the hazard burden (the range, nature, distribution and significance of the hazards), take these questions into consideration:

- What are the hazards associated with our activities?

- What is the significance of the hazards (high/low)?

- How does the nature and significance of the hazards vary across the different parts of our organisation?

- How does the nature and significance of the hazards vary over time?

- Are we succeeding in eliminating or reducing hazards?

- What impact are changes in our business having on the nature and significance of hazards?

Measure your (Q)HS(E) management system

Your health and safety management system (or QHSE management system) converts your uncontrolled hazards to controlled risks. The key elements include:

- Policy

- Organising

- Planning and implementation

- Performance measuring

- Audit and review

Take note that your performance measurement system should cover each element of your HS (or QHSE) management system.

Measure your failure (also called reactive monitoring)

We will not be discussing it here but see the HSE guideline for details.

Measure your health and safety (or overall QHSE) culture

A positive QHSE culture can be measured through the following activities:

- Control

- Communication

- Cooperation

- Competence

Measure progress with plans and objectives

An effective QHSE plan progress measuring should be based on “SMART” KPIs (key performance indicators) and OKRs (objective and key results).

- Specific

- Measurable

- Attainable

- Realistic/Relevant

- Timebound

We have a chapter dedicated to this in our latest ebook, The Clear and Complete Guide to a Digitised QHSE Organisation, which you can download for free here.

Measure your management arrangements and risk control systems

Measuring management arrangements and risk control systems (the levels 1 and 2 of Figure 1) should cover three aspects:

- Capability

- Compliance (implementation)

- Deployment

Measure workplace precautions

The output of risk control system design is having suitable workplace precautions (level 3 in Figure 1) in place at the point of risk activity. Measuring compliance provides information in order to determine if workplace precautions are in place, operating, and are effective.

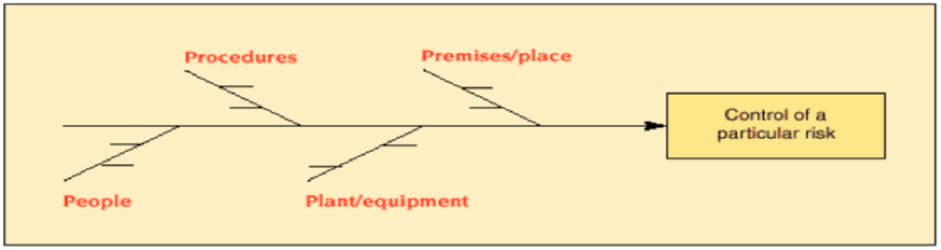

This is basically comparing against a defined standard and considers workplace precautions under the four P’s: premises, plant and materials, procedures, and people, which is illustrated here:

When should we measure?

When should we measure?

Measuring QHSE indicators is an ongoing activity and is a continuous process. Here is a summary of factors to consider for planning your measuring activities appropriately:

- Suitable intervals to ensure that specific planned milestones are achieved

- The potential for change from one state to another over time

- The relative importance of the activity or particular precaution relative to the overall control of risk

- Where intervals for monitoring are prescribed by legislation

- Where there is evidence that there is non-compliance

- Where there is evidence of compliance

- The relative frequency and time at which a particular activity takes place

Who should measure?

As mentioned earlier, QHSE performance needs to be measured at each management level of your company. On a company level, you should decide how to allocate these responsibilities for all types of monitoring at all levels in your management chain.

Your managers and supervisors are responsible for monitoring the progress of plans and objectives and their compliance with standards—activities and tasks allocated to their competent subordinates.

How to measure?

Measuring QHSE performance can gather needed information and data through any of the following:

- Direct observation of conditions and people’s behavior (inspections)

- Talking to people to gather facts and their experiences as well as their views and opinions

- Written reports, documents and records

Your handy guide to a balanced scorecard

- Identify your key processes

- Analyse your key management arrangements and risk control systems to create a flow chart of your processes

- Identify critical measures for each of your management arrangement and risk control system. Consider these questions:

- What outcome do we want?

- When do we want it?

- How would we know if we achieved the desired outcome?

- What are people expected to do?

- What do they need to be able to do it?

- When should they do it?

- What result should it produce?

- How would we know that people are doing what they should be doing?

- Establish baselines for your measures

- Establish goals or targets for your measures

- Assign people for collecting and analysing data

- Compare actual performance with your target

- Decide on corrective action

- Review your measures

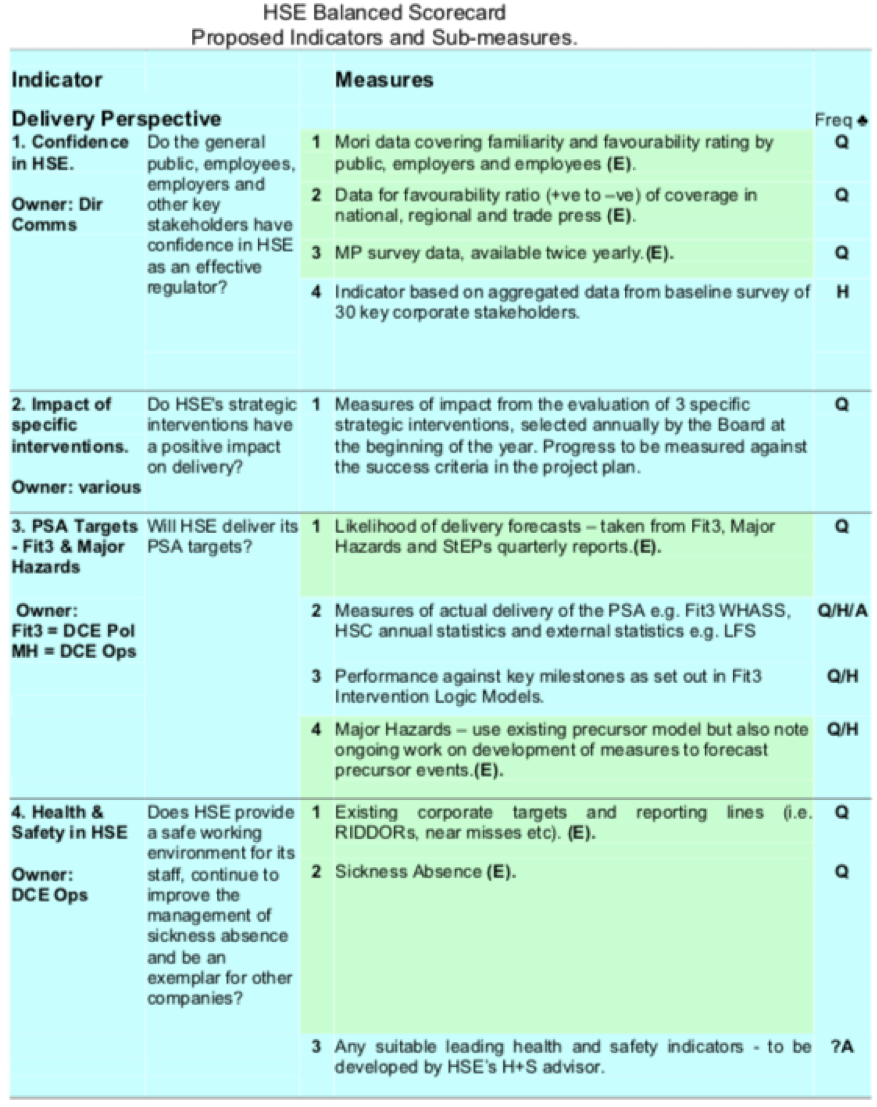

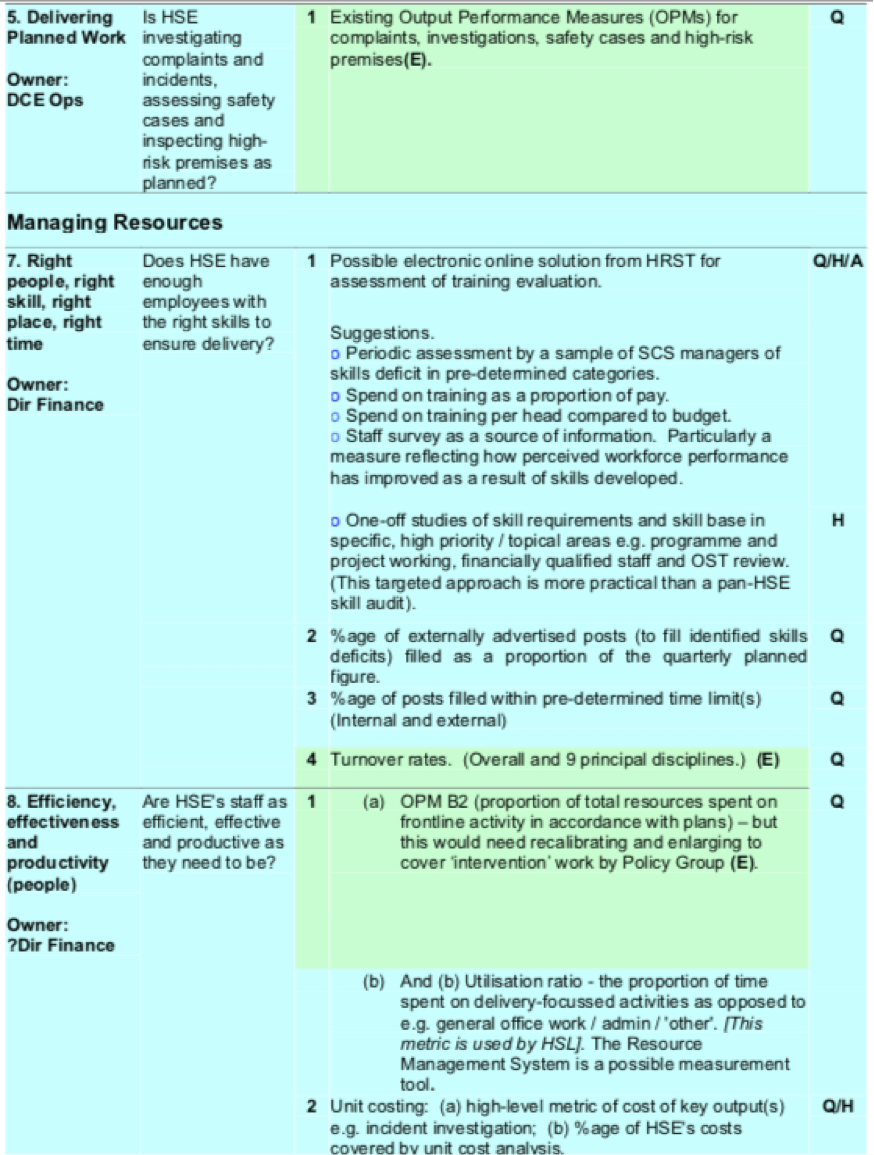

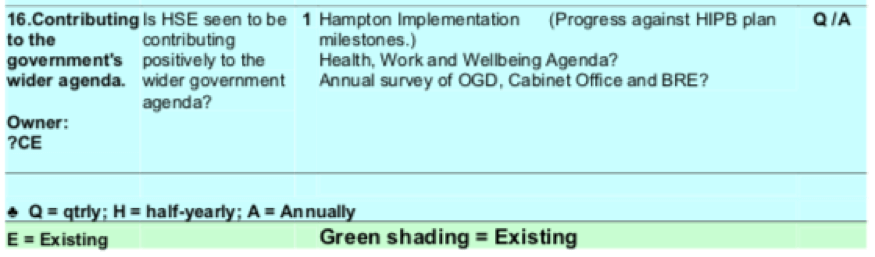

Here is an example of an HSE Balanced Scorecard (Health and Safety Executive, 2005). For the entire document, please follow the link.

Taking your QHSE scorecard to the next level

As digitisation and digitalisation slowly creep into construction and as more construction companies use technology tools for project management, even your QHSE system can now be managed using a construction project management software.

This is definitely a game changer as it would save a lot of hours on unnecessary admin tasks and report making. With the perfect construction management software, you can take your QHSE system with you anytime and anywhere and can be accessed in real time by the right people.

Further reading: Applying construction technology solutions for a safer worksite.

If you want to learn more on how digitising your construction processes can help improve your worksite safety (including your QHSE system and workflows), why not download our ebook, 6 Keys to Staying Competitive, for free today?