An amazing opportunity

According to Jan Mischke, Senior Fellow at McKinsey & Company and one of the writers of the well-known McKinsey report ‘Reinventing Construction: A Route to Higher Productivity‘, the gap in productivity between average economy and construction is up to $1.6tn a year. This is a shocking statistic that highlights the potential that global construction has if productivity problems are overcome.

‘The opportunity for the building sector just from moving to economy average is more than $1.6trn a year. That’s half the global annual infrastructure spending. Just by doing things better, not hiring a single additional person we could build half of the world’s infrastructure’, says Jan Mischke.

The number gains even more importance if we take into account that productivity has been flat for approximately two decades now. And we are talking for a $10tn sector which is expected to grow over $15tn in the next 12-13 years.

These remarks were discussed in the course of the European ConTech Summit on January 30th in London. The Summit was co-hosted by LetsBuild and Construction News and opened its doors to many remarkable innovators and forward-thinkers of the building sector.

The good news is that the industry is at the verge of a fundamental change. On a global level a strong sense of urgency has started to become apparent. But as Mr. Mischke smartly suggests such a strategic shift takes time:

‘There is this change as we speak. I don’t think that anyone can predict whether it’s going to be changing over the next three years or over the next 30 years. But construction is changing. Digital is one of the biggest drivers of that change and one of the biggest necessities and opportunities for the industry, too’.

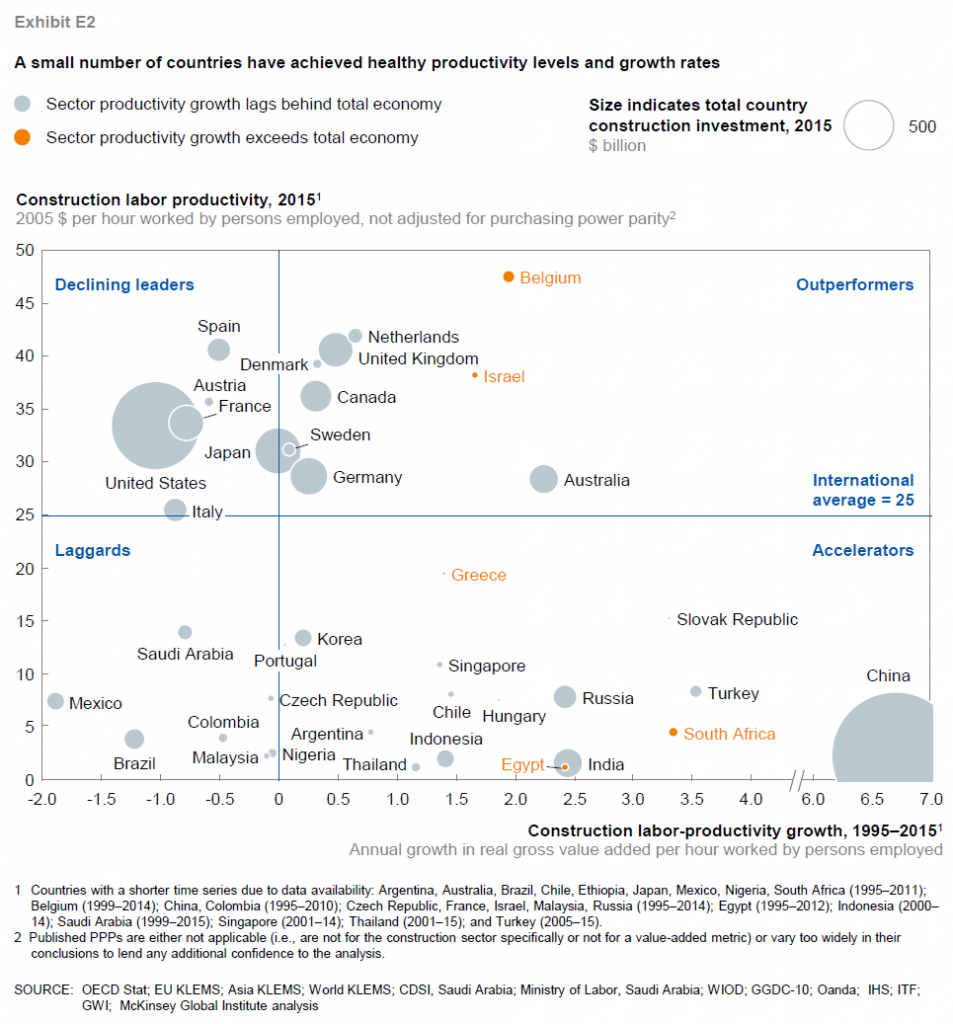

Another interesting element is the diversity of the global building sector. In simple words, the productivity growth and level seems to vary depending on the sub-sector of construction that you are focusing on.

For instance, Jan Mischke notices that the oil and gas sector is performing better in terms of productivity due to its consistent push for attracting the best engineers and standardizing various phases of the process. To the contrary, fragmented smaller trades, such as plumbing and framing, often have to deal with negative productivity levels.

Watch the full summit!

Do you want to take a sneak peek on everything that happened on the European ConTech Summit? Then all you have to do is adding your email address to the form below and unlocking the whole event.

What is behind the productivity struggle?

By now, it’s evident that construction is facing serious productivity problems. But, we need to know the reasons why things are the way they are. McKinsey & Company recently carried out an in-depth research in order to analyse how the companies at the front-line perform and what are the industry dynamics that drive this behavior.

As explained by Jan Mischke, the main reasons behind the serious productivity pains in construction could be summarized to the following:

External forces

Starting from the potential external forces which could affect the industry’s performance, increased site and project perplexity appears to be a vital factor. It’s worth-mentioning that 21% of the total global spending in construction concerns projects greater than $1bn. According to the existing statistics, this type of projects perform usually worse than small projects in terms of productivity.

Maintenance and refurbishment projects also hurt productivity growth in construction and absorb 50% of the total global spending. This is very problematic if we take into account that maintenance and refurbishment projects are often associated with low productivity rates.

Mistrust and litigious culture

The second indispensable parameter that Jan Mischke points out has to do with the hostile atmosphere on which many projects are established. Mistrust, litigious culture and tendering scenarios full of claims are common phenomena in the building sector. The need for a more collaborative and innovative approach in the industry is stronger than ever.

‘There is a majority out there who is scared that someone is going to eat their cake. Well, someone is going to eat their cake if they don’t change’, underlines Mr. Mischke.

Poor project management

On a firm level, poor project management and execution on site are hurting the construction sector. Many times the design process is deemed to be problematic. More analytically, numerous projects start with too little planning (this is usually the case) and then project agents have to change its structure which leads to even more problems. Other times, projects start with too much planning but without appropriate risk accounting.

For Jan Mischke, these are some of the most critical issues that affect productivity in construction which in combination of course with the lack of digitisation and the general lack of investment makes the current problem even bigger.

How to fight low productivity

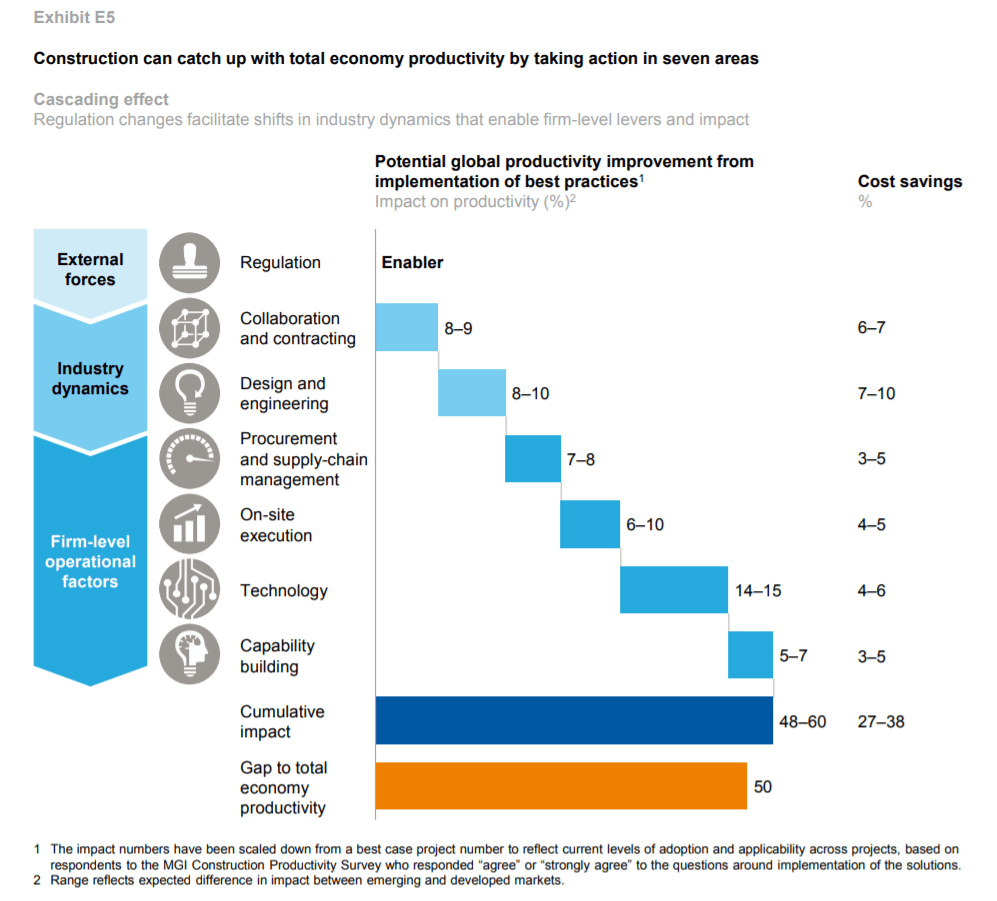

Despite its serious flaws both in terms of structure and culture, the building sector has still many reasons to be optimistic. More specifically, based on the bottom up assessment of McKinsey & Company, there are seven crucial levers of change for construction:

1. Regulation: Actions involve speeding up permitting processes, harmonizing building codes and in many cases also mandating technology. The mandatory use of BIM in the UK can be a representative example. These steps could help a lot with with minimizing corruption and informality.

2. Collaboration and contracting: The industry needs to stray further from the current hostile environment that is part of many building projects. Contractors and owners should work together to optimize things. Best value should be prioritized over lower cost. In other words, we need to go a step further and embrace integrated project delivery.

3. Repurpose design and engineering processes: In many cases, this is just about investing more in the process. For instance, as Jan Mischke suggests:

‘Instead of investing 3% in the process invest 8% or 10%. This will make a significant difference. It will pay off!’

On top of that, the industry needs to find a way to optimize the way the entire chain works and collaborates. Therefore, the institutionalisation of value engineering into the design process should be a priority.

4. Optimize supply chain management: About 50% of the cost in construction is in materials. That’s why procurement centralisation and standardisation of the supply chain workflow can truly boost productivity.

5. On-site execution: There is a strong need for scheduling work on site in a more efficient manner. There are many different disciplines that need to be carefully planned and coordinated. Workforce deployment and standardisation of certain on-site tasks can provide tremendous help. It goes without saying that the use of digital tools is anticipated to speed up on-site execution in the future and push for a more integrated building process.

6. Capability building: Focus on workforce training can also be something that will eventually transform the industry. The advent of new digital tools and equipment on site has created a strong need for the industry to invest in training of the workers on-site. That would be a solid step towards increasing productivity in the sector.

7. Digital technologies: Technology investments could have an impact of 14-15% on the sector’s productivity. And that’s not all. Productivity growth could result in cost savings of 4-6%, as shown on the diagram above. Construction is at the moment the least digitised sector even after agriculture. It is understandable, then, that the potential from the implementation of digital technologies can be huge.

Why technology is construction’s best friend

We mentioned earlier that the building industry is at the verge of a fundamental change. Digital technologies should be seen as the strongest ally that the sector has right now.

During his talk in the European ConTech Summit, Jan Mischke was kind enough to describe the main ways in which technology can revolutionise construction:

Computer vision: There is a lot of activity around computer vision at the moment. The use of drones and robots can allow for nearly perfect site surveying through the collection and process of valuable project data. Like that, project agents and stakeholders can obtain a full picture of the progress and the challenges that workers might face on site. Many costly and time-consuming conflicts can be eventually avoided thanks to effective site surveying.

Additionally, the creation of a building’s digital twin could add great precision during the construction process and easily point out any deviations from the original plan. On top of that, digital twins can provide valuable feedback for future similar projects (eg. precision on the type of materials needed on site).

Next generation BIM: Many construction companies are attempting now to dissect their organisations to the traditional part and the digital part where they try to work on the entire BIM chain. Elements such as 5D BIM could provide the industry with increased transparency when it comes to design, progress visualisation and costing. It is apparent, in other words, that BIM can contribute to the building process on many different levels.

Digital project collaboration and mobility: The use of construction management mobile apps can be an excellent example in this category. The effortless and straightforward connection of the numerous project agents will lead to improved progress-tracking and real-time collaboration. Both elements can accelerate the construction process and empower the connection between the site and the office.

IoT and advanced analytics: The ability to analyse in depth all the data that you have acquired from a construction site can be powerful. It can help you detect what elements you need to optimize during the building process. On-site material monitoring, equipment and labor productivity are only a few of the areas where IoT and advanced analytics could be extremely helpful.

Innovative materials, techniques and equipment: The development of lightweight materials and new innovative building techniques can boost modular construction. Off-site construction can accelerate the building process and decrease cost. Furthermore, the use of robotics on large scale repetitive site tasks (eg. bricklaying) can speed up construction projects and increase safety on site.

Construction will eventually change!

So far, there has been a lot of discussion about the issues that the construction industry is battling against and the strong resistance towards change that is observed in many cases. But this doesn’t mean that construction isn’t going to change after all.

Jan Mischke is convinced that the industry will eventually change and there are many reasons which allow us to believe that:

- Escalated demands and requirements in terms of cost, sustainability, quality, project complexity and affordable housing.

- New disruptive players (eg. China and Singapore) are anticipated to enter the market on a global level. Increased transparency in the global market is also regarded as a decisive factor according to McKinsey & Company.

- The advent of disruptive technologies will continue at a fast pace. As a result, project processes and methodologies will change dramatically in the upcoming years.

- Migrant labor limitations and increasing wage rates are anticipated to transform the workforce type.

- Digital marketplace players can put some pressure on suppliers and change the way contractors are used to work.

Wrapping it up

All in all, it is evident that the construction industry has a lot of work ahead and that lack of productivity is really hurting the sector. Nonetheless, as Jan Mischke suggested during his European ConTech Summit talk digital technologies and brave investments can make this fundamental change for construction come true.