CUSTOMER STORY

-

+20% average efficiency gains on site

-

€5k monthly savings from materials delivered at the right time

VolkerFitzpatrick is one of the UK’s leading engineering and construction companies, providing specialist building, rail, civil engineering and industry focussed skills to a range of market sectors including commercial, industrial, education, rail, aviation, waste and energy through its six different businesses in the UK.

In particular, the Rail Division covers the development and maintenance of rail depots and infrastructure. LetsBuild’s product GenieBelt was used in the West Anglia Main Line (WAML) Capacity Improvement Project.

United Kingdom

Main Contractor

10,001+ employees

about the project

The WAML project, part of Network Rail’s Lee Valley Rail Programme

The WAML project was part of Network Rail’s Lee Valley Rail Programme to deliver £170m of improvements across the Upper Lee Valley from 2017 to 2019.

VolkerFitzpatrick, as principal contractor was building 5.5km of new track which will reduce congestion for passengers and support regeneration across the Upper Lee Valley area.

Throughout the project multiple teams undertook large volumes of work in time-controlled periods. Work was done on the weekends because there was a requirement to keep the areas operational during peak time periods.

“Within the industry, the programme is king. If we don’t deliver on time, it’s going to cost us more money or certainly cost someone more money. So when using LetsBuild to provide that visibility up the chain, sales managers, senior managers can see what is going on the project.”

getting to understand the client’s needs

Multiple applications, scattered information and laborious processes

When project participants use different and disconnected communication channels, it takes time to channel feedback and enquiries to the right people. This can result in downtime and unnecessary costs.

This was an everyday problem for Matt Ghinn, Project Director at VolkerFitzpatrick. Before implementing GenieBelt, progress reports, key milestones and/or problems arisen on the project were communicated using a combination of hour-by-hour programmes, text messages, WhatsApp groups, emails, formal reports, Excel forms, and phone calls.

“The teams on site were already reporting through WhatsApp messages and emails. They were handwriting answers as well. We just told them to do it in one platform. And they just picked it up!”

The traditional methods were laborious and it required enormous effort to issue consistent messages out to teams, to capture accurate programme data, and provide reliable updates on on-site progress. With so many different sources of data collection, the risk of vital information being missed or incorrectly actioned between teams was high.

“Traditionally, photos were taken, site diaries were updated, progress was being updated, dashboards were being produced but they were all individual tasks. This required a lot of effort in terms of admin work,” says Matt Ghinn.

Moreover, VolkerFitzpatrick was working with static programmes that were not easily updated to reflect actual progress.

- Disjointed Communication Channels

- Inefficient Data Collection and Reporting

- Static Project Planning

- Delayed Problem Detection

- Financial Risks

- Unsuitable Tools for Construction Management

our solution

Timely sharing of critical information

Matt was finding it difficult to maintain an overview of the project. There was a lot of pressure on him to deliver and he needed to execute on an hour-by-hour project plan without full insight into what was happening on site. Formal reports were made every 4-12 hours only and that meant that impacted schedule problems were not always known until the end of the 12-hour shift, resulting in project delays.

These delays would inevitably disrupt site activities and in most cases cause project delays. For Matt and his company, this could potentially mean €100,000s in penalty payments to the client.

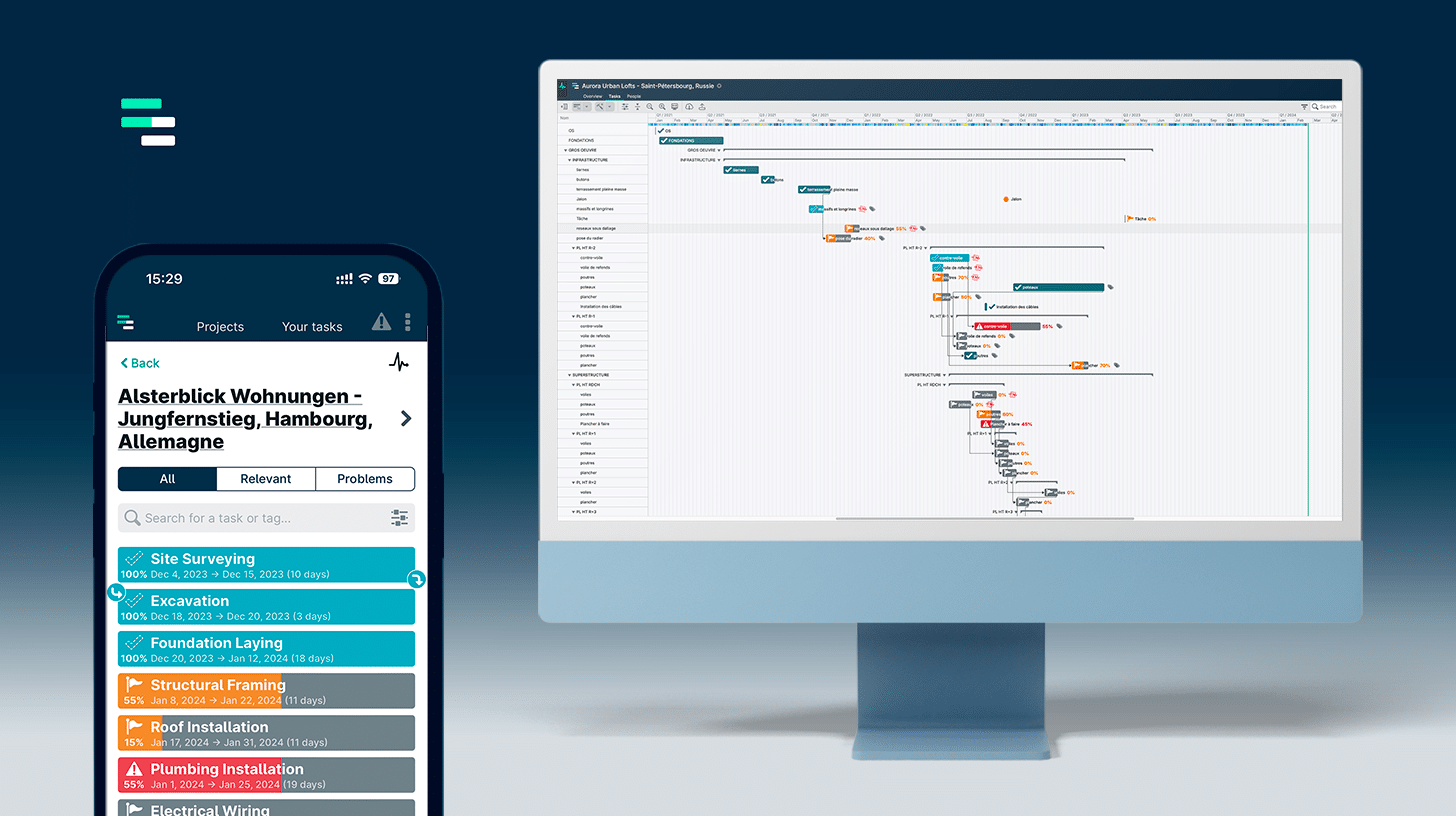

GenieBelt has changed that, providing live real-time reporting that can be accessed at any time that suits. Matt quickly saw the benefits when, during a meeting, he received a notification in the app that part of the project was not progressing. Thanks to the overview he had gained with the new tool, he was able to immediately cancel a €10,000 concrete order that would otherwise have been wasted.

GenieBelt is also able to generate a report instantly from the collated data, including progress updates, photos, messages and problems that have been reported and/or communicated by teams, as well as information on where delays may have occurred.

“Our programme is updated at site level. That means that the operative supervisor provides us the information from site. So we get photos; we get updates. This allows the team to take more ownership and provides us with visibility across the whole site team,

- Real-time Reporting and Notifications

- Integrated Communication and Data Collection

- Improved Project Visibility

- Increased Efficiency

- Cost Savings

- Ease of Use and Quick Adoption

Implementation & Results

An easy tool that connects site to office

Matt realised that WhatsApp and Excel, good as they are, are not made for construction. The different digital tools he and his colleagues were using simply weren’t suitable for the purpose of managing such a time-critical project. So Matt set out to find what he calls “The WhatsApp for construction”.

Based on a recommendation from a friend, Matt decided to test out the real-time progress reporting and communication platform offered by LetsBuild.

“I was introduced to the platform on Wednesday and decided it was great. We got it set up on Thursday. I briefed the team on Friday. We were using it that weekend and we got great returns.”

Fast forward two weeks and Matt had already seen an increase from 60% to 85% in the percentage of scheduled activities completed on time. Over the next three months, the project went from being 5 weeks behind schedule to being on time. And Matt has calculated that he is saving on average €5,000 / month because materials are delivered at the right time, decisions are made faster and he has fewer disputes with his subcontractors because everyone is working on the same platform.

In spite of his management’s concerns with introducing a new digital tool to rail workers when their existing tools were “good enough”, the site teams were trained in just one day and kicked off already the next day on site. GenieBelt has been proven to be an extremely easy tool for construction teams on site to use. On the WAML project, it only took VolkerFitzpatrick three days to get GenieBelt up and running.

Matt Ghinn further elaborates on the importance of user interface and how teams need to be able to work with simple reporting tools.

“LetsBuild saves us time because it automatically generates reports for the information that is in the system. So we have definitely seen the benefit and it means that people have more time to get an idea of what their job is and deliver safety on site.”

conclusion

Effective collaboration with subcontractors

With the help of LetsBuild’s on-site planning and progress reporting product GenieBelt, VolkerFitzpatrick has full visibility of the project, which has led them to work effectively with their subcontractors.

“We often had subcontractors arriving on site and not getting any work done because the previous tasks haven’t been completed. With LetsBuild and their product GenieBelt, we have visibility of project progress. So if there is going to be a delay, we let them know a week beforehand!”

Stop sitting on the sidelines. Stay ahead of the game with LetsBuild

Four apps right at your arsenal to streamline your build. The formula is simple. If you win, we win. LetsBuild around the way you build.

How to see everything happening on site

Discover how management in 934 construction companies achieved peace of mind by ELIMINATING the use of text messages, phone calls, WhatsApp, email, Excel, paperwork, and formal reports.